BM-V Harkom Packaging Machine with Volumetric Filler provides an efficient and user-friendly packaging machine solution. Let’s take a look at the features of BM-V Volumetric Filling Packaging Machine.

With increasingly challenging living conditions, finding ways to make processes easier is essential. The ability to complete more work in less time is a crucial factor in selecting a packaging machine. Therefore, BM-V Harkom Packaging Machine with Volumetric Filler is designed to enhance efficiency. With the BM-V Volumetric Packaging Machine, you can accelerate your packaging machine processes, ensuring higher productivity.

The Harkom Packaging Machine is designed for free-fall applications, ensuring efficient and precise packaging for various products. This advanced Harkom Packaging Machine is ideal for handling products with densities that remain within the desired sensitivity range. Weight control is managed through six or eight volume-adjustable containers, which can be customized to accommodate different product types. The weight accuracy of the Harkom Packaging Machine depends on the size and homogeneity of the product, ensuring consistent results.

All product-contact surfaces of the Harkom Packaging Machine are made from AISI 304 stainless steel, fully meeting food safety standards. Additionally, the easy-to-change collar set allows for quick and seamless adjustments to different packaging types, enhancing the versatility of the Harkom Packaging Machine.

Precise package length adjustments in the Packaging Machine are simplified with an adjustable speckle sensor, ensuring accuracy and efficiency. The automatic stop operation prevents unprinted or incorrect prints, enhancing the reliability of the Packaging Machine. Equipped with an AC motor-driven film sliding unit, this advanced Packaging Machine also features a pneumatically driven horizontal jaw welding and cutting unit, optimizing the packaging process.

Depending on the type of Packaging Machine used, both cold and hot welding techniques can be applied, offering flexibility for different packaging needs. Designed to comply with CE standards, this Packaging Machine ensures safety and performance. Additionally, with multiple language options and an easy-to-use touch screen, the Packaging Machine provides a user-friendly and efficient packaging experience.

Errors in the packaging machine are minimized, ensuring smooth operation. The BM-V Volumetric Harkom Packaging Machine has been developed with precision in every aspect and has gained the trust of its users. This packaging machine is widely recommended and praised for its efficiency. Thanks to its reliability, troubleshooting is rarely needed, and operational losses are minimized. With this Harkom Packaging Machine, users can enhance productivity while protecting their products.

Contact us for different types of packaging machine solutions, products, and capacities.

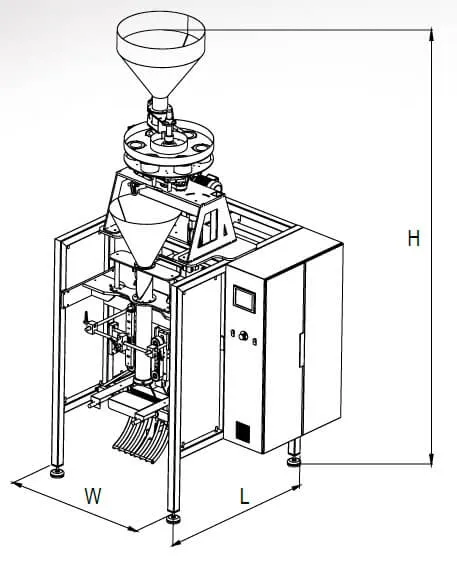

| Width | BM290 1660mm / BM400 1720mm |

| Length | BM290 2050mm / BM400 2050mm |

| Height | BM290 2910mm / BM400 3150mm |

| Weight | BM290 650kg / BM400 700kg |

| Production Speed (Number/Min) | 50 |

| Package Length | BM290 60mm-350mm / BM400 60mm-700mm |

| Package Width | BM290 60mm-270mm / BM400 60mm-380mm |

| Film Coil Diameter | 300mm |

| Film Coil Width | BM290 130mm-580mm / BM400 130mm-830mm |

| Power Consumption | 5.5 Kw |

| Operating Voltage | 380V 3 Phase 50Hz |

| Air Consumption | 150 Lt/Dakika - Minute |

| Air Pressure (min.) |